Electrical Engineering Expertise

Hardware Engineering

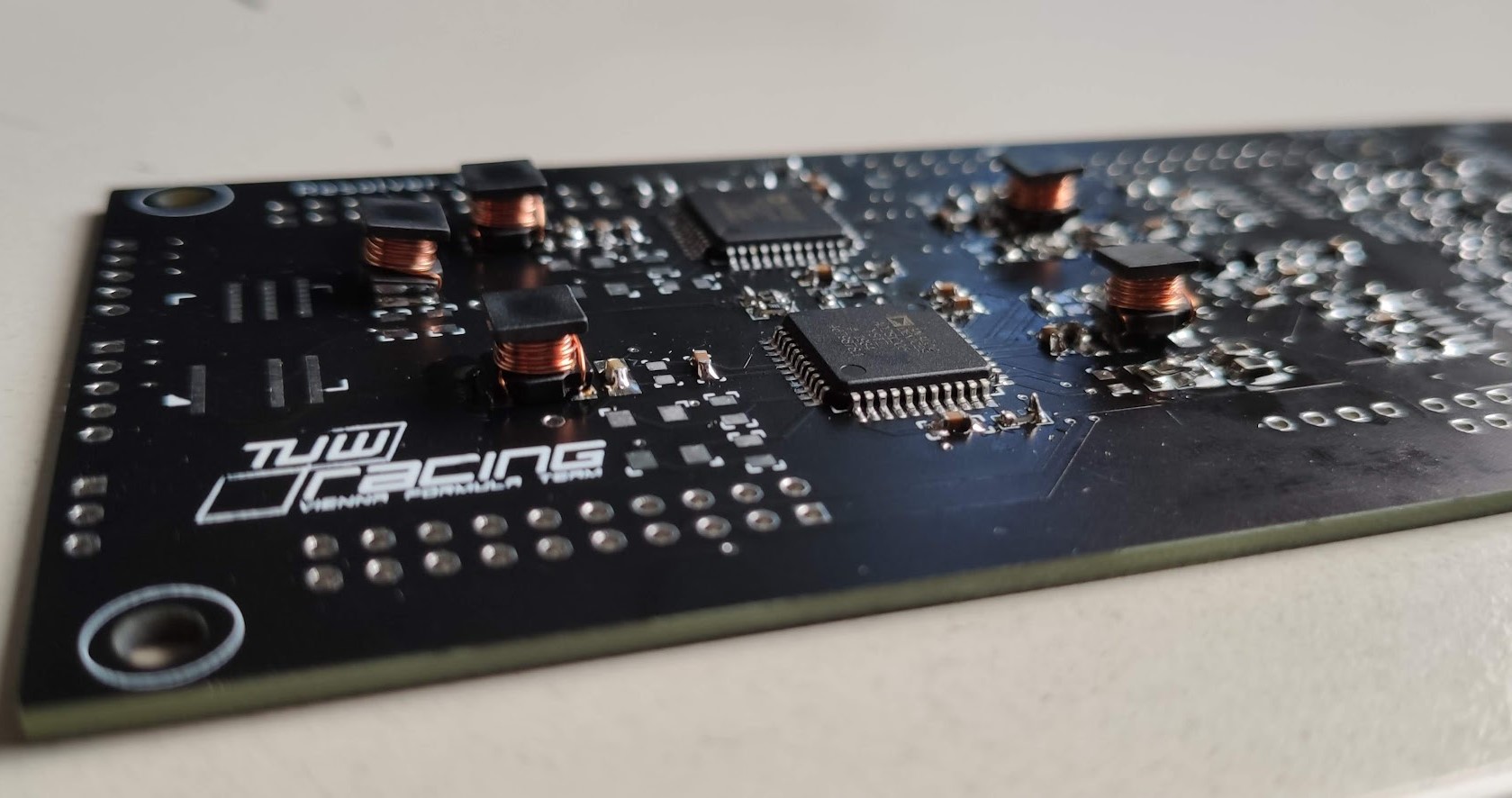

From schematic capture to working prototypes - bringing electrical designs to life through systematic design, simulation, and validation.

Experience gained through TU Wien Racing team projects and lab work, focusing on real-world application and manufacturability.

PCB Design & Layout

Translating circuit concepts into manufacturable PCB layouts using industry-standard EDA tools. My approach focuses on signal integrity, power distribution, and design for manufacturability.

- KiCAD Proficiency: Schematic capture, component library management, multi-layer PCB layout, and Gerber file generation for production.

- Eagle/Fusion 360: Experience with Autodesk's integrated electronics design workflow, combining mechanical and electrical design.

- Signal Integrity: Understanding of trace routing, ground planes, via placement, and EMI considerations for reliable circuit operation.

- Design Rules & DFM: Implementing design rule checks, considering manufacturing constraints, and optimizing layouts for cost-effective production.

Tools I Use

KiCAD

Eagle/Fusion

LTspice

Oscilloscope

Circuit Simulation & Analysis

Validating circuit designs through comprehensive simulation before committing to hardware fabrication. This approach saves time and reduces costly design iterations.

- LTspice Analysis: Transient analysis, AC/DC sweeps, noise analysis, and Monte Carlo simulations for component tolerance evaluation.

- Model Validation: Using manufacturer SPICE models and creating custom behavioral models when needed for accurate simulation results.

- Performance Optimization: Iterative design refinement through parametric sweeps and worst-case analysis to ensure robust operation.

- Mixed-Signal Simulation: Combining analog and digital circuit elements to validate complete system behavior.

Prototyping & Testing

Bringing designs to life through hands-on assembly and validation. Through my time in the TU Wien Racing team I gained experience in designing, manufacturing and troubleshooting PCBs. There is a certain joy when soldering the PCBs, it feels so productive.

Key Skills

- Board Assembly: Experience with through-hole and surface-mount (SMD) soldering techniques for assembling prototypes.

- Testing & Debugging: Utilizing standard lab equipment (multimeters, oscilloscopes, logic analyzers) to test circuit functionality and troubleshoot issues.

- Iterative Design: Comfortable with the iterative process of testing, refining designs, and creating improved hardware versions.

- Documentation: Maintaining detailed test logs and design notes for reproducible results and future reference.

The hands-on experience from racing team projects has taught me the importance of robust design practices and thorough testing protocols in real-world applications.